Share This Article

Roz Kaldor-Aroni has had an extensive corporate career initially as lawyer, then as CEO of a not for profit medical research organisation and now she has turned her hand to ice cream.

Why ice cream? Did you know that Australian’s and New Zealanders eat more icecream per head of population than anywhere else in the world? No nor did I but that is not the main reason. The main reason is Roz has a sweet tooth and she is a great cook, plus she has always loved making sweet treats. Moreover her schooling was not just in law, she did physics and maths and as you will learn she is very interested in how to make food that not only tastes incredible, it is also good for you. Finally her organisation has a really strong social purpose giving a portion of the profits to charity.

Crispy > Hi Roz welcome to Almanak. Can you tell us how your started business and made the transition from corporate executive to the queen of ice cream?

Roz > It started when my husband gave me an icecream recipe book which had been endorsed on the cover by Heston Blumenthal and in the back was all the maths… I am a trained scientist, I did science and law at uni and so I went straight to the back first to look at this maths. I fell down the ice cream rabbit hole because I have a terrible sweet tooth and the idea of doing maths and sweet together felt like heaven to me.

I fell down the ice cream rabbit hole…

I started training at William Angliss catering school in Melbourne learning to make gelato, but in that course much to my disappointment I was encouraged to make gelato using premade powders and pastes. They promoted this approach because the manufacturers of the machinery for gelato want gelato shops to make a consistent product. Even though the class was taught how to make original recipes, they were basically encouraging people who wanted to run a gelato shop that they should just use the pre-made stuff if they wanted to have an easy life!

Roz > I was clear from that point I only wanted to make a product that is made from scratch. I was also clear that I was not going to make a product based on chemicals, I was only going to make a product based on all natural products.

Crispy > Was all this while you were CEO of the Not For Profit company?

Roz > Yes, I had been running that for six years and I was starting to feel burnt out running that organisation. It was the right time to leave. My husband reminded me I had originally committed to five years and I needed a change. Also the organisation was now essentially self funding and they didn’t need me anymore. It was a perfect time for my transition.

So I took myself off for more training to Italy at Carpigiani Gelato University in Bologna. While I was there I found answers to a few important gelato questions.

We did a bunch of recipes with egg yolk as the emulsifier and the same recipes using a chemical called mono and diglyceride of fatty acids (MDG). The taste difference was so dramatic. The recipes with egg yolk were exceptional compared with the ones using MDG. I sat and said to myself that I am never going to use chemicals because the taste difference is just massive; it is chalk and cheese.

I still did not know what I was going to do with my newfound gelato knowledge, I wasn’t thinking of a scoop shop, I wanted to find a way to leverage my knowledge and to give back to the community. We looked at a lot of models and ultimately decided to follow the ‘Who Gives a Crap’ model which gives a portion of profits to charity. But this requires a scalable product, plus you need to be profitable, make money and give back to the charity. We selected Oz Harvest, they are a very successful food rescue organisation, who made it very easy to become a sponsor of their organisation.

Living in Melbourne, Victoria we are in the dairy heartland of Australia and so we have a lot of capacity for contract manufacturing, allowing me to make a product at scale.

I also didn’t realise until this point that gelato and ice cream are opposites, they are made quite differently. Gelato is high sugar and low fat, icecream is the opposite. We now know that sugar is the enemy, so I did not want to make a high sugar product. I wanted to make a better for you product that tasted really yummy.

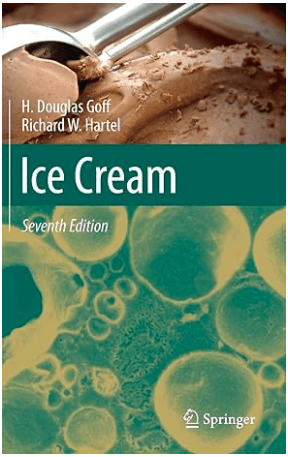

Slightly depressed I realised I have been learning and training in all the wrong stuff. I needed to learn about ice cream. The way I started was to buy the text book from the world leading academic in ice cream by Professor Douglas Goff (who knew there was one). So I started writing to him and asking questions. He invited me to his masterclass which was held in Guelph, Canada (a small city about ninety minutes from Toronto). It was the dead of winter. I was there for a week and that is where I developed all my current recipes. I sat in class and Doug explained that lactose free milk and cream were three times sweeter than normal milk and cream.

So I had a moment of inspiration, does that mean I can use less sugar in my recipe if I make it lactose free? Well yes of course, but I didn’t know that, so with him I explored how to make the recipes work with much less sugar. He helped me with the maths and so I came back just before COVID with a bunch of exciting recipes.

I decided that I could go further on making my recipes healthier, using the Australian Health Star Rating System, I developed a product that had a 3 Health Star Rating (out of 5), there were no other indulgent ice creams that have that number of stars, most have 1 – 2 stars.

Crispy > So tell me are you doing the manufacturing yourself?

Roz > No and when I got back from Canada I was searching for a contract manufacturer but they were all really busy because of COVID. It was not until I found a manufacturer that had been making premium product for restaurants and hospitality that I could get my products made. Their business was really hurting due to all the COVID lockdowns meaning no one was going to restaurants, and they had only done contract manufacturing once before.

They have turned out to be an amazing partner and so good to work with. Even though the maths in all my recipes is infallible (all my recipes are done on a spreadsheet), what I didn’t know were the material handling limitations when you scale up the production.

Things you can do at home with small scale churns and a Thermomix, does not work the same when you get to large scale production, there are physical limitations to what you can do. I learned a lot about pumping and flow. We did lots of trials until we got things to work perfectly.

Crispy > The product is lactose free, can you educate me on how that works?

Roz > Let me explain the chemistry of lactose. It’s made of two sugars that are bonded together (a disaccharide) namely glucose and galactose. What happens in your gut is an enzyme called lactase which splits the two sugars, so they are separate and by doing that you have increased the sweetness by 3 times.

So that is how I do it. We make it lactose free by adding the enzyme to the tank and splitting the sugars. With ice cream you have to age the product overnight for reasons that I will explain and we use that time to break down the lactose. The reason you need to age ice cream overnight is that you smash the proteins and fats into tiny parts with a homogeniser (the same way milk is homogenised). You do this because you want the fats and proteins to be a little unstable, when you pump air into the product (under pressure). The aging makes the fats perfectly able to capture and hold the air (the same as whipped cream).

Crispy > Did you do a lot of tasting all the premium ice cream’s on the market?

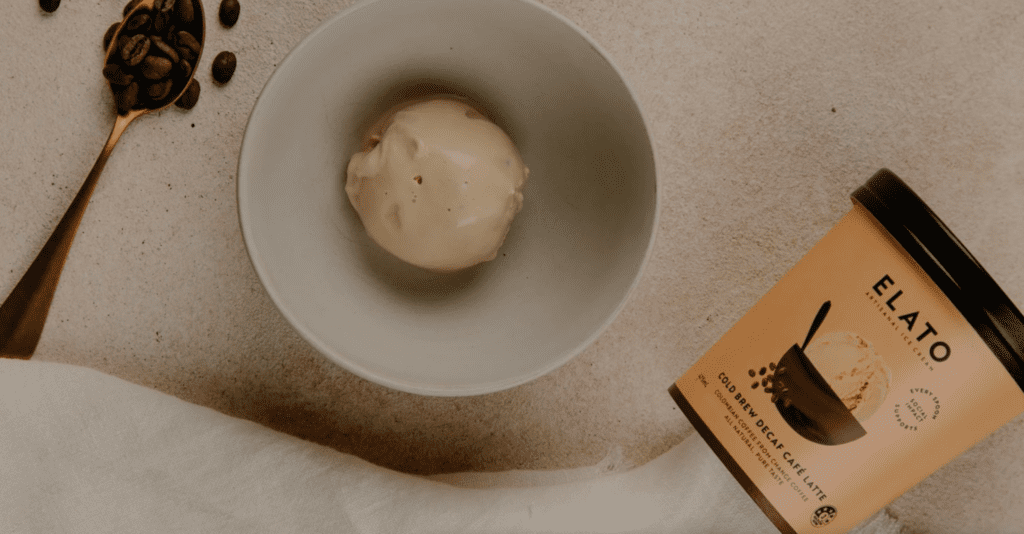

Roz > When making my product, I always have the lead competitor on my bench. I knew we had to taste better than our competitors. We have four flavours triple vanilla and cold brew decaf coffee (both dairy). We have a chocolate (vegan) and a new one called fig ripple (which is dairy again).

Crispy > How did you take it to market?

Roz > we had some advisors who were super helpful and guided us to start with independent supermarkets, who have lower hurdle rates (the number of products that sell each week), to keep the shelf space. Supermarkets are landlords they need you to sell product to stay on the shelf, that is their way of you paying the rent!

We pitched to a national distributor doing a blind taste test (with the lead competitor). They were blown away picking our product over the lead competition in each of our flavours. So we got into 300 stores around the country by summer of 2021.

Once you are ranged somewhere you can go and see the big supermarkets. We pitched to Woolies first, as they also work closely with Oz Harvest. They were super helpful, suggesting we start selling in their smaller Woolworths brand ‘Metro’ where we were able to prove our business, before scaling to Woolworth supermarkets.

It was fantastic. We were top performer of new ice cream brands and also won ‘Metro’ Supplier of the Year in 2022!

Crispy > So that got you into the big supermarkets?

Roz > Well the timing was perfect. The bigger supermarkets were undergoing a full review of all the products in the range looking for the best products to select in each sub category. We were the only brand that was both in the really yummy and indulgent plus also being in the better for you category.

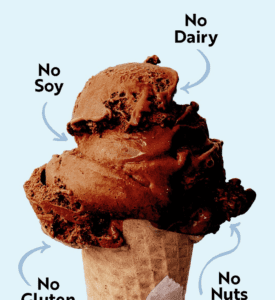

Better for you is not just the 30% less added sugar. We also add protein and add fibre. We also don’t use any chemicals at all. Everyone else is using some form of chemicals, but we have gone all the way back with all our ingredients to ensure that no chemicals are used in the extraction of ingredients from nature.

every time we ran production, the seeds from the figs blocked the ice cream machine and six times it blew it up. Ice cream all over the factory!

As a result we have made a beautiful gourmet natural product with premium natural ingredients. Cheaper ice creams use chemical and non natural ingredients and they are also full of air. If you are buying a two litre tub for $5 then more than half that tub is air as air is a free ingredient!

Crispy > So it sounds like you have made a product that people are loving?

Roz > Yes and we have won a lot of awards for our ice cream, we have won best Australian ice cream award from Melbourne Royal and gold medals from Sydney Royal and the Queensland Dairy Industry as well as lots of Silver medals.

We are now in over 1000 stores in two years so it has been going really well.

Crispy > Is there something you would do differently if you had time over again with what you know now?

Roz > I would not go into a perishable frozen product, it makes everything hard and challenging. For instance our fig ripple comes from a partner who work with female asylum seekers and refugees to train them to be work ready. They make this amazing fig jam and on tasting it I knew immediately it was the perfect ingredient for a fig ripple ice cream. But as we worked on the recipe every time we ran production, the seeds from the figs blocked the ice cream machine and six times it blew it up. Ice cream all over the factory! We made it work but it was a big effort.

Crispy > Tell us more about the purpose driven nature of Elato

Roz > What keeps me going is that I want to generate a lot of money to gift to Oz Harvest, it’s not about being successful to make a lot of money. All our suppliers are committed to social impact too, the ingredients are fair trade and it means that we are able to make a real contribution to the community.

I am also passionate about getting people to eat a healthier product. We are easier to fit into a healthier diet with 30% less sugar and fibre and protein. However when you taste Elato you would never know that this product is better for you. As a result our tag line is “seriously delicious and a little bit healthy”.

our tag line is “seriously delicious and a little bit healthy”

Crispy > Roz thanks for catching up with us today.

Roz > It’s great to talk to you thanks for the opportunity.

Elato is currently only available in Australia but they are exploring opportunities for future expansion into new markets.

LINKS